CENTRO Factory

CENTRO's factory plant is unsurpassed in the furniture world for distinctive craftsmanship.

Our production facility (powered with state of the art European equipment / German made Edge Bander and Italian CNC suite etc) affords the highest quality finish. CENTRO are one of the few plants with ISO 9001:2015 QMS International Accreditation supporting innovative sustainable development.

Factory Details

- Established:1992

- Size:22,000 square meter

- Staff:Over 450

- Qualification:Awards ISO 9001:2015

- Location:Guang Dong Province, China

- Products:Residential and hotel furniture

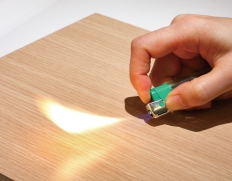

Italian edge banding technique

Sliding door with integrated noise reduction and dust resistance

Moisture protection on cabinet outer layer

Surface enhancement on inner cabinet

Soft close door damper

Scratch resistant coating

On demand fire retardant

Our factory plant offers perfectly coordinated solutions, from product prototype right up to complete production lines. The comprehensive solutions on offer cover CNC station, Beam Saws, Veneer Splicer, Veneer Cutter, Automatic Sanding & Calibrating System, UV Varnishing Machine, Automatic Spray Paint System. We focus on advance equipment whilst ensuring high product quality and precision, together with the corresponding operators, satisfy client specific requests both today and in the future.

Veneer Cutter

Italy

CNC Working Center

Italy

Edgebander

Germany

Panel Saw

Germany

CNC Drilling & Milling

China

Calibrating Sanding Machine

Italy

Our Commitment

Professional Machinery

We focus on advance equipment whilst ensuring high product quality and precision, together with the corresponding operators, satisfy client specific requests both today and in the future.

Skillful craftsmen

Employees are part of one big corporate family, we have co-workers with 15 years of great contributions.

Quality Management System

Our factory plant implemented and maintains a QMS ISO9001:2015 to ensure high quality products and reliable services.

Achieving the highest standard

Final assembly will be applied to every single batch in order to ensure our good quality.